Case Studies | Manufacturing Industry

- New Product Development Process - Ownes-Illinois

Successfully Implemented Automation of “New product development ( Innovation Process)” in Chicago, USA for O-I Headquarter in Australia

The Client

Ownes – Illinois, Headquarters, Australia

A fortune 500 company headquartered in Australia, the largest manufacturer of liquor bottles in the world.

Industry

Liquor Bottle Manufacturing

Challenges

It was challenging to track the complex progress of the New Product Development Process(NPDi) in the SAP RPM module as, O-I has been doing product design, modeling, manufacturing at different placed located in different countries. So, there was a need for the workflow to keep track of the progress of the complete project and notify to different roles in the process as per the completion of previous work tasks.

Solution

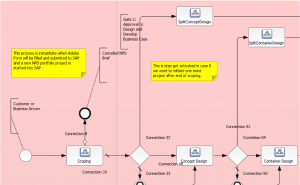

Pericent team had participated in workflow modeling the complex Innovation Process having approx 400 workshops with a completely adaptive case management process into BPM Modeler. And, implemented a complete process with bi-directional integration with SAP RPM module using Webservices/SOAP along with SAP Implementation team.

The NPDI process implementation was comprising the 8-9 complex subprocess process models, every step from innovation, design, modeling, manufacturing, and delivery of the manufactured products.

Process Model

Business benefits

Various roles in the process only need to enter the business data of process in SAP, in the backend compelling the workflow task, which assigns the task to the next performer and informs him via email along with reminder and escalation.

Technology Used and Architecture

BPM Platform, Java/J2EE

- Dealer Code Creation/Dealer Onboarding Process, USHA International, India

Challenges

When a dealer is created or onboarded, the process involves a lot of compliance/policy to be met plus approvals. The customer has SAP in place for the set of records but the workflow is maintained through the BPM. Any change of information or updating can easily be taken care of by meeting with business policies.

The Client

USHA International Limited, India

Industry

Manufacturing

Solutions

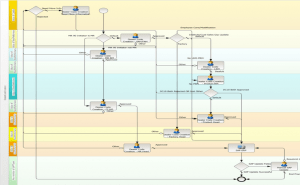

Implementation automation of Dealer Onboarding Process and integrated with SAP for final onboarding of dealer into SAP after completing due diligence and multiple approvals.

Process Model

Business Benefits

Dealer onboarding has considerably reduced the time to onboard a vendor

Technology Used and Architecture

bpmEdge BPMS – Enterprise class Business Process Automation and Management Platform

- Material to Material Transfer, USHA International, India

Challenges

USHA had a scenario where an online system generates a request and process the requests of material transferring between two organizations/location. Through this application, the material transfer procedure occurs from the recipient side, which sends a request for a particular material along with its details, to the material sender organization.

The Client

USHA International Limited, India

Industry

Manufacturing

Solutions

Implementation automation of Material to Material Transfer and integrated with SAP after completing multiple approvals.

Business Benefits

It has reduced the time and efforts of coordination a lot as per customer.

Technology Used and Architecture

bpmEdge BPMS – Enterprise class Business Process Automation and Management Platform